Product List

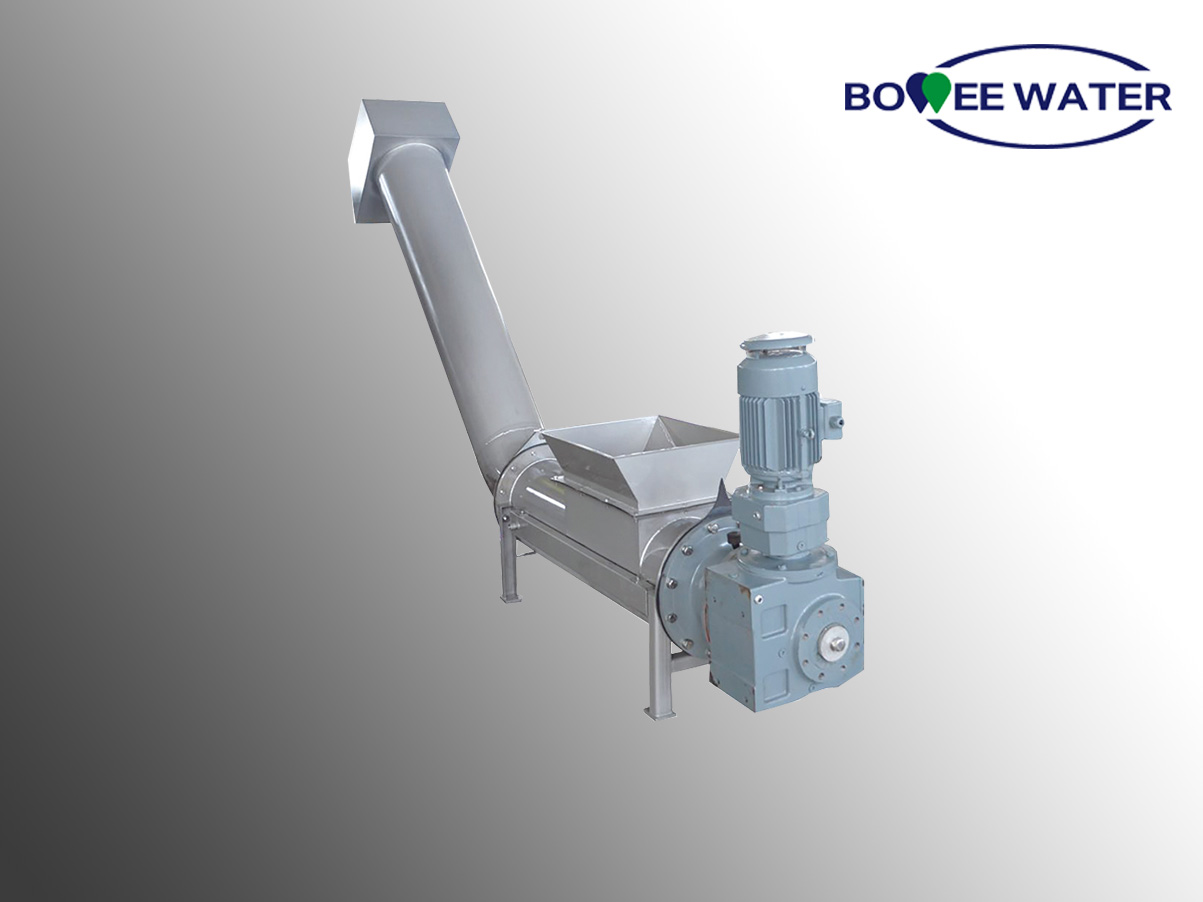

Screw compactor is the bar screen supporting facilities, screw press presses the dirt carried by bar screen, in order to reduce the dirt moisture and reduce the volume of sewage.

Specifications:

Dimension: Customized

Material: SS304, SS316 or Customized

Capacity:1.5-6m3/h

Screw diameter:260mm,300mm,360mm,420mm

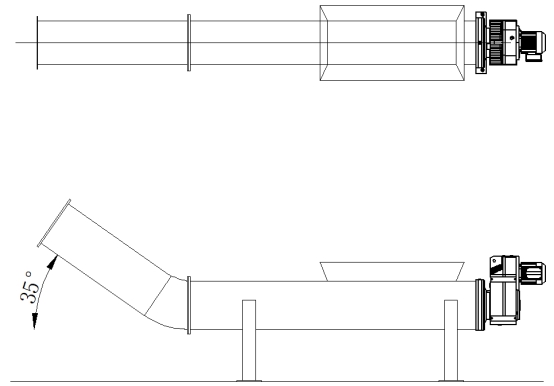

Conveying length: 6m

Motor brand: First-class motor, Nord or SEW is optional

-

Description

Screw compactor is the bar screen supporting facilities, screw press presses the dirt carried by bar screen, in order to reduce the dirt moisture and reduce the volume of sewage.

Screw compactor consist of press screw, screw pipe, transmission parts, feed hopper and discharge hopper. The dirt from the feed hopper into screw pipe, under the function of press screw, press, dewatering and conveying to the discharge mouth.

Drive shaft rotation speed reducer drive the blade, helix Angle to produce thrust forward to squeeze into the squeeze tube material, after extruding the material is being exhausted from port discharge, and waste water is separated into sink to achieve the purpose of separation.

-

Applications

· It is used to dehydrate and compress the residue from the sewage pumping station, the sewage treatment plant and the water plant.

· Dehydrate and compress the residue in papermaking, sugar making, wine making, food processing, slaughtering, leather, textile, printing, petrochemical and other industrial wastewater treatment.

-

Technical parameters

Model

Parameter

BWSC-260

BWSC-300

BWSC-360

BWSC-420

Capacity(m3/h)

1.5

3

4.5

6

Screw diameter(mm)

260

300

360

420

Conveying length(mm)

6

6

6

6

Power(kW)

2.2

3

4

5.5

-

Advantages

Simple structure, small cover area, easy installation and maintenance; In addition to the slag discharge mouth open, the rest parts can be enclosed stamped, will not spill material, reduce air pollution.

-

Related Products